CONCRETE

The Sustainable Choice

Low Carbon Ready Mixed Concrete

Guidelines

Topics covered are reaching Net-Zero, EPDs, industry carbon reduction goals, case studies and more…

Specifying Sustainable Concrete

Continuing Education

Sustainable concrete is difficult to define. There are many factors that can influence the way concrete is manufactured, designed, built, used and recycled that ultimately affect the environmental footprint of the structures built with concrete. Whether one is designing a building, pavement, bridge or dam, concrete is an important component used as foundation and superstructure, and these structures can have a significant impact on the environment throughout their lifecycle.

- Analyze the difference between performance-based specification and prescriptive specifications.

- Evaluate how performance-based specifications can improve performance and lower environmental impact of concrete structures.

- Learn how to implement performance-based specifications in projects.

- Demonstrate the importance of balancing structural and architectural performance of concrete with green building strategies.

AIA CREDIT: LU/ELECTIVE

AIA COURSE NUMBER: AR122019-2

Use the learning objectives above to focus your study as you read this article. To earn credit and obtain a certificate of completion, visit http://go.hw.net/AR122019-2 to view the entire CEU and complete the quiz. CEU courses are free of charge once you create a new learner account; returning users log in as usual.

Concrete Innovations

Continuing Education

Concrete is the most widely used building product in the world. For the most part, concrete is made locally with local materials. It is cost effective, readily available, strong and durable. Although conventional concrete can tackle most jobs, it is also the material of choice for the tallest buildings in the world and infrastructure designed to last centuries. New concrete products and manufacturing methods are enhancing concrete’s performance to tackle modern challenges. This article explores some of these latest innovations.

- Understand new technologies used in concrete manufacturing.

- Discover how innovative concrete products can improve project performance.

- Learn how to implement the latest concrete innovations in building and infrastructure projects.

- Demonstrate the importance of incorporating new technologies to enhance resilience and sustainability in the built environment.

AIA CREDIT: LU/ELECTIVE

AIA COURSE NUMBER: AR082019-2

Use the learning objectives above to focus your study as you read this article. To earn credit and obtain a certificate of completion, visit

http://go.hw.net/AR082019-2 to view the entire CEU and complete the quiz. CEU courses are free of charge once you create a new learner account; returning users log in as usual.

Concrete Facts

About Sustainability

The ready mixed concrete industry is dedicated to upholding the principles of sustainable development-development that meets the needs of the present without compromising the ability of future generations to meet their own needs-by attempting to balance social, economic and environmental impacts.

Reducing the carbon footprint of the built environment

Alive to the challenge of climate change, the cement and concrete industries are working to lower the embodied carbon of buildings and infrastructure.

The world research is underway to address the sustainability and environmental impacts of the production and use of cement and concrete.

These efforts range from adapting the composition of cement and concrete, to reducing the greenhouse gas emissions of production, and quantifying and reducing the environmental impacts and costs during their useful lifespans and the end-of-life of infrastructure facilities and buildings.

Read MoreThe Challenge

While much attention has been given to decarbonizing the transportation and energy sectors, there is a growing challenge to lower the carbon footprint associated with the built environment to meet the emission reduction targets of the Paris Agreement adopted by many nations in 2016.

Responding to this challenge, cement and concrete producers around the world are revisiting existing and exploring new technologies to lower the carbon content associated with both the manufacture and use of their products. For some, the goal is to achieve an ambitious net-zero target by 2050.

Speculation varies but it is widely thought that roughly 8% of global GHG emissions come from the industrial processes of cement, iron and steel, and the chemical industries.

Because concrete is the most widely used building product in the world, lowering the energy and carbon footprint of cement production logically is the first place to start.

Changing the way we make cement

Currently, over 4 Gt of cement are produced globally each year, resulting in more than 2 Gt of CO2 emissions, about 6% of the global total of greenhouse gas (GHG) emissions).

These emissions stem largely from the process of cement manufacturing, which requires extremely high temperatures (over 1,200 °C) in a kiln, as well as from the chemical decomposition of limestone.

Strategies being pursued by leading industry players to lower CO2 emissions in the cement-making process include introducing other fuel sources such as biomass for the kiln heating process, in lieu of coal, or making changes to the fundamental composition of cement.

Lafarge Canada and Lehigh Hanson use biosolids as fuel in cement manufacturing at their respective BC plants in Richmond and Delta. By replacing the use of coal, this can reduce greenhouse gas emissions by approximately 5,000 metric tons per year (tpy) of CO2e per plant.

Other technologies for generating the heat needed to make cement are being explored as well, including the use of hydrogen-based fuels or electric heaters that run on renewable energy sources.

Feasibility studies are underway on technologies that combine biomass, hydrogen and other energy sources that could reduce or eliminate fossil fuel CO₂ emissions.

Coupled with retrofitting older cement production plants and designing new more energy-efficient facilities that reduce the demand for off-site energy the overall volume of carbon emissions associated with cement production is declining.

Carbon capture, storage and sequestration (CCSS) is another way to reduce the emissions from clinker production, as well as lowering the clinker content of cement by blending supplementary cementitious materials (SCM) such as fly ash, or slag (a waste stream byproduct from steel production). These practices are emerging in the industry. Research on alternative binders for cement holds the potential for even greater reductions in carbon emissions.

As an example, most cement companies in North America offer blended hydraulic cements with up to 15% limestone by mass, that generates approximately 10% less CO2 and thereby reducing the embodied carbon per ton of cement.

Certain blends of the product line can reduce the amount of CO2 in the manufacturing process by as much as 20-25% as compared to Ordinary Portland Cement (OPC) while maintaining product performance requirements.

The beauty of this technology is that the product is available now and, in most cases, can be specified in lieu of OPC without sacrificing performance characteristics. Additionally, blended hydraulic cements may be used in conjunction with other concrete GHG mitigation strategies leading to even greater CO2 reduction.

Designers and specifiers can easily specify the use of blended hydraulic cements as they calculate and compare embodied carbon impacts of materials prior to consumption through the various tools available today.

How we use cement and concrete in the built environment is also an area ripe with carbon-reducing potential.

Changing how we use cement and concrete

Apart from changes to the actual composition of cement, changing how cement and concrete are used can also lower the carbon footprint of the built environment.

Optimizing the design of structures to be more energy-efficient, more resistant to climate-related impacts, and more price-competitive in the marketplace would greatly influence the development and affordability of housing in our rapidly expanding cities and towns.

Designing buildings or infrastructure that require lesser volumes of concrete that can be manufactured offsite or that employ construction techniques such as 3D printing technologies also hold great promise.

More climate-resilient concrete could lengthen the useful lifespan of buildings, thereby lowering the dollar and carbon costs of replacement or renovation. So too, designing buildings and communities to better withstand and recover from extreme weather-related incidents such as floods, wildfires, storms, or heat waves also provides an emissions reduction benefit.

Increasing the longevity of buildings and infrastructure, improving quality control and the generation and reuse of demolition waste will significantly lower GHG emissions over time.

Waste product use and reuse provides additional opportunities as substitutes for fossil fuels and raw materials, which also addresses our waste problem as a society.

The elimination of typical construction/demolition waste materials such as wood and petroleum-based products from our landfills can provide an environmental credit rather than a debit when viewed from the perspective of the circular economy.

Growing recognition and calculation of the untapped potential of atmospheric C02 reabsorption (carbonation) by exposed concrete will also alter the balance in carbon accounting for concrete relative to other building products.

Policy Approaches

While many technological approaches are being explored to lower the embodied carbon of buildings and infrastructure assets such as roads, bridges and transportation facilities, policy and regulatory measures are also being deployed as well.

Governments are the key players in infrastructure investments and as such can exert a profound role in the design, construction, and the operation of public facilities through permitting financing, and other associated policy measures.

Measuring the embodied carbon content of various building materials is rapidly becoming an important tool for the design and regulation of structures. The various carbon calculator tools in play are still in their infancy but have already been legislated in some jurisdictions as a means to offset or lower carbon emissions. Lifecycle Assessment (LCA) tools of varying sophistication are being used to formulate embodied energy or carbon indices.

As noted by Dr. Jeremy Gregory, the Executive Director of the Concrete Sustainability Hub at MIT Environmental Product Declarations amount to a nutritional label about a product’s environmental impact. Until recently, creating EPDs required several months of independent, individual verification, and was very time-consuming and expensive.

According to Kate Simonen, a co-founder of the Carbon Leadership Forum, embodied emissions—those released from the manufacturing of industrial materials are going to rise, at least as a percentage of the overall impact.

“As building codes become more stringent and the electrical grid decarbonizes, the relative proportion of impact due to material production increases. We simply don’t have time to approach this in a linear fashion”, she notes.

For example, prohibiting or limiting fossil fuel use or requiring lower carbon-intensive technologies could stimulate profound changes in business practices.

Other policy measures include public support for clean energy research and development. If coupled with the enormous leverage of governmental procurement of products and services with lower carbon content this could profoundly change industry behaviour.

Tax incentives, grants, loan guarantees, feed-in-tariffs, and contracts for the deployment of innovative technology solutions also will stimulate change.

Summing Up

The stark realities of the need to reduce the carbon content of the built environment have not been lost on key players in the cement and concrete industries, nor by policymakers at all levels of government.

Working in partnership with industry associations can strengthen the drive for decarbonization and the sharing of information on best practices. This is a process that requires open dialogue and a willingness to work cooperatively.

Many industry associations have come together to articulate clear messages for policymakers on practical approaches to fundamentally lower the carbon footprint of the built environment and to promote greater resiliency and risk reduction.

While there is no shortage of ideas to meet this challenge, the window of opportunity is very tight. Major investments in new technologies and sound public policies that place a premium on resiliency, efficiency and sustainability are needed now. Time is not on our side and as history has shown us over and over again, time waits for no one.

__________________________

By William Larson and Frank Came

William Larson is the recently retired Vice President Marketing at CalPortland. He also serves as Chairman, of the Steering Committee coordinating the development of the Pacific Northwest Building Resilience Coalition since its inception in October 2016.

Frank Came is Managing Director of Globe Advisors. He was the Project Director for the Globe Advisors study on Carbon Sequestration of Forest-Based Wood Building Products completed in 2017 for the Pacific Northwest Building Resilience Coalition.

Construction industry stakeholders-including project owners, designers, contractors and product manufacturers-are especially affected by the challenges of sustainable development since the built environment has significant environmental, social and economic impact on our lives and planet. On one hand, our built environment provides us with places to live and work and contributes to a robust economy and societal needs. On the other, operating our buildings, houses and infrastructure consumes enormous amounts of energy and valuable resources. Building products require natural resources and energy to produce and transport. New construction projects can burden natural habitats.

We are dedicated to continuous improvement through product and process improvements. The industry continues to increase the use of recycled materials, including industrial by-products, thus conserving valuable natural resources and reducing process energy required to manufacture concrete. The industry continues to explore new ways to further reduce the carbon footprint through the development of innovative cements and concrete mixtures. Concrete companies also strive to improve manufacturing processes, including the use of alternative energy sources, to minimize the energy of production and the associated greenhouse gas emissions. Finally, the industry continues to enhance transportation efficiency and delivery methods to reduce the environmental impact of the construction process.

EPDs

Environmental Product Declarations

LEED v4, Architecture 2030 Challenge for Products and the International Green Construction Code request building product manufacturers to submit Environmental Product Declarations (EPDs) to demonstrate environmental performance of their products. LEED v4 provides 2 points for a project that can document: 1) having 20 products and materials with EPDs and 2) having 50% of the products by cost demonstrating lower impacts than industry baselines through EPDs. LEED v4 values different types of EPDs as follows:

- Self declared EPDs are worth 1/4 value (not third party verified)

- Industry average EPDs (hotlink back to location with (CRMCA +EPE+20170317)) are worth 1/2 value (third party verified)

- Product Specific EPDs are worth full value (third party verified)

In LEED v4, a “product” is defined by the distinct function it serves. That means concrete has the advantage of contributing significantly because of concrete’s wide range of applications or functions. For example, footings, foundations walls, shear walls, bearing walls, columns, beams, slabs, sidewalks and parking areas, each with a unique mix design, would all be considered different products in LEED v4 and therefore contribute significantly to the 20 required products or the 50% of products by cost used in a building.

Click here to download a guide to specifying concrete for LEED v4 projects.

This Environmental Product Declaration (EPD) covers concrete mixes produced by Concrete Association of BC (Concrete BC) members. This EPD was independently verified by NSF International in accordance with ISO 14025:2006 and ISO 21930:2017. The life cycle assessment was independently reviewed in accordance ISO 14044 and the referenced PCR.

Here’s a step-by-step instructional regarding how to use an EPD

The National Ready-Mixed Concrete Association (NRMCA) periodically presents Environmental Product Declarations (EPDs). EPDs are third party verified (certified) reports published by product manufacturers that provide quality assured and comparable information regarding environmental performance of their products. Well established in other parts of the world, EPDs are starting to appear in the US as the common methodology for assessing environmental performance of a product. The upcoming LEED v4 Rating System and Architecture 2030 Challenge for Products are starting the demand for EPDs. Join us for an informative 1-1/2 hour webinar as we offer a brief overview of EPDs, the Life Cycle Assessment (LCA) that supports them and the Product Category Rules (PCRs) that sets the ground rules for them. In addition, the webinar will discuss NRMCA’s EPD Program and present the first certified EPD for concrete in North America.

NEW Watch a Recorded Webinar on EPDs

Concrete & LEED Canada

New Construction (NC) 1.0

The Canada Green Building Council (CaGBC) has released version 1.0 of Leadership in Energy and Environmental Design (LEED) for new construction (NC) in Canada. This version, LEED Canada – NC v.1.0, references relevant Canadian legislation, standards, and government programs.

Using concrete can facilitate the process of obtaining LEED Green Building certification. LEED is a point rating system to evaluate the environmental performance of a building. The system is credit based, allowing projects to earn points for environmentally friendly actions taken during the building process.

LEED was launched in an effort to develop a “consensus-based, market-driven rating system to accelerate the development and implementation of green building practices.” The program is not rigidly structured; i.e., not every project must meet identical requirements to qualify. The flexibility in the rating system allows each project team to “select the green strategies that will best meet the project’s goals.”

The LEED rating system has five main credit categories:

-

Sustainable Sites

-

Water Efficiency

-

Energy and Atmosphere

-

Materials and Resources

-

Indoor Environmental Quality

Each category is divided into credits. Detailed information on the LEED program and project certification process is available on the CaGBC website, www.cagbc.ca. The program outlines the intent, requirements, technologies, and strategies for meeting each credit. Credits are broken down into individual points. Additional points can be earned for innovation, exceptional environmental performance, and use of a LEED-accredited professional on the project team.

A building requires at least 26 points for certification. Silver, gold, and platinum levels are also available.

14pts – Sustainable Sites

5pts – Water Efficiency

17pts – Energy and Atmosphere

14pts – Materials & Resources

15pts – Indoor Environmental Quality

65pts – Total Core LEED Rating System Points

5pts – Innovation & Design Process Points

The following are suggestions for earning LEED points through the use of cement and concrete products. The designations correspond to LEED ratings system credit categories.

(Sustainable Sites Credit 3)

Cement can be used to solidify and stabilize contaminated soils and reduce leaching concentrations to below regulatory levels. Documentation is required indicating the site was contaminated and the remediation performed. This credit is worth 1 point.

(Sustainable Sites Credit 5.1)

Concrete parking garages on the lower floors of a building can be used to limit site disturbance, including earthwork and clearing vegetation. For example, one criterion is to limit site disturbance to 12m (40 ft) beyond the building perimeter. Parking garages within buildings help maintain existing natural areas that would be consumed by paved parking. This credit is worth 1 point.

(Sustainable Sites Credit 5.2)

Concrete parking garages on the lower floors of a building can be used to help reduce the footprint of the development. In this context the building footprint includes the building, access roads, and parking. Parking garages within buildings reduce the building footprint by reducing paved parking areas. This requirement can be met by exceeding the local zoning’s open space requirement for the site by 25%. This credit is worth 1 point.

(Sustainable Sites Credit 6.1)

The intent of this credit is to limit disruption and pollution of natural water flows by managing storm water runoff. Using pervious concrete will reduce the rate and quantity of storm water runoff because it increases infiltration of stormwater. Pervious concrete contains coarse aggregate, little or no fine aggregate, and insufficient cement paste to fill the voids between the coarse aggregate. It results in concrete with a high volume of voids (20% to 35%) and a high permeability that allows water to flow through easily. On building sites where the existing imperviousness is greater then 50%, the technical requirement for this credit requires reducing the rate and quantity of stormwater runoff by 25%. On building sites where the existing imperviousness is less than 50%, the requirement specifies that the post-development discharge rate and quantity from the site shall not exceed the pre-development rate and quantity. This credit is worth 1 point.

(Sustainable Sites Credit 7.1)

Use light-colored/high-albedo materials (reflectance of at least 0.3) for at least 30% of the site’s non-roof impervious surfaces. This requirement can be met by using portland cement concrete, rather than asphalt for 30% of all sidewalks, parking lots, drives and other impervious surfaces. Another option include placing a minimum of 50% of parking spaces underground or covered by structured parking.

Albedo, which in this context is synonymous with solar reflectance, is the ratio of the amount of solar radiation reflected from a material to the amount that shines on the material. Solar radiation includes the ultraviolet as well as the visible spectrum. Generally, light-colored surfaces have a high albedo, but this is not always the case. Surfaces with lower albedos absorb more solar radiation. The absorbed radiation is converted into heat and the surface gets hotter. Where paved surfaces are required, using materials with higher albedos will reduce the heat island effect—consequently saving energy by reducing the demand for air conditioning—and improve air quality. As the temperature of urban areas increases, so does the probability of smog and pollution. Smog episodes rarely occur when the temperature is below 21°C.

Portland cement concrete generally has a reflectance of approximately 0.35, although it can vary. Measured values are reported in the range of 0.4 to 0.5. For “white” portland cement, values are reported in the range of 0.7 to 0.8. New asphalt concrete generally has a reflectance of approximately 0.05, and asphalt concrete five or more years old has a reflectance of approximately 0.10 to 0.15. This credit is worth 1 point.

(Energy & Atmosphere Prerequisite Credit 2)

All new buildings must demonstrate energy savings using a whole building energy simulation program. The two compliance paths for new buildings are (1) to show that the building complies with Natural Resources Canada’s Commercial Building Incentive Program (CBIP) requirement by reducing energy consumption by at least 25% relative to the Model National Energy Code for Buildings 1997 (MNECB), or (2) to reduce energy cost consumption of the building by at least 18% relative to ASHRAE/IESNA 90.1-1999.

The 2 compliance paths for major renovations to existing buildings are to (1) reduce energy consumption by at least 10% relative to the MNECB, or (2) comply with ASHRAE/IESNA 90.1-1999.

Many engineering consulting firms have the capability to perform whole building energy simulations to determine energy consumption and costs as required using computer-based programs such as CBIP-EE4, DOE2 or EnergyPlus. When concrete is considered, it is important to use programs like these that calculate yearly energy use on an hourly basis. Such programs are needed to capture the beneficial thermal mass effects of concrete.

Components constructed of concrete generally are considered “mass.” This means the components have enough heat-storage capacity to moderate daily temperature swings. Buildings constructed of cast-in-place, tilt-up, and insulating concrete forms (ICF) possess thermal mass which helps moderate indoor temperature extremes and reduces peak heating and cooling loads. Thermal mass can make a significant contribution to energy savings; this is demonstrated when mass is incorporated into an energy consumption simulation program. When buildings are properly designed and optimized, incorporating thermal mass can lead to a reduction in heating, ventilating, and air-conditioning equipment capacity. Reduced equipment capacity can represent energy and construction cost savings. This item is required and is not worth any points.

(Energy Credit 1)

This credit is allowed if energy cost savings can be shown compared to a base building that meets the requirements of MNECB or ANSI/ASHRAE/IESNA 90.1-1999. Insulated concrete which exhibits the prerequisite thermal mass characteristics noted above, will most likely be eligible for points when used in conjunction with other energy savings measures,. The number of points awarded will depend on the building, climate, fuel costs, and minimum requirements of the standards.

When using MNECB, from 1 to 10 points are awarded for energy cost savings of 24% to 64% for new buildings and 15% to 55% for existing buildings. When using ASHRAE/IESNA 90.1-1999, from 1 to 10 points are awarded for energy cost savings of 15% to 60% for new buildings and 5% to 50% for existing buildings.

(Materials Credit 1)

The purpose of this credit is to leave the main portion of the building structure and shell in place when renovating. The building shell includes the exterior skin and framing but excludes window assemblies, interior walls, floor coverings, and ceiling systems. This credit should be obtainable when renovating buildings with a concrete skin, since concrete in buildings generally has a long life. This is worth 1 point if 75% of the existing building structure/shell is left in place, 2 points if 95% is left in place, or 3 points if 50% of non-shell areas are maintained.

(Materials Credit 2)

This credit is received for diverting construction, demolition, and land clearing waste from landfill disposal. It is awarded based on diverting at least 50% by weight or volume of the above listed materials. Since concrete is a relatively heavy construction material and is frequently crushed and recycled into aggregate for road bases or construction fill, this credit should be obtainable when concrete buildings are demolished. This credit is worth 1 point if 50% of the construction, demolition, and land clearing waste is recycled or salvaged and 2 points for 75%.

For concrete, either the credit for building reuse or the credit for construction waste management can be applied for, but not both, because the concrete structure is either reused or recycled into another use.

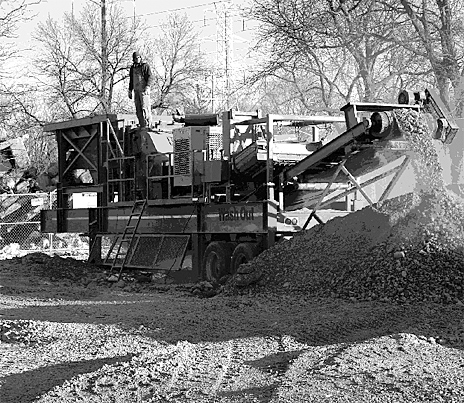

This picture shows a machine crushing portions of concrete walls, columns, and floors. The crushed concrete was reused as fill material.

(Materials Credit 4)

The requirements of this credit are for using materials with recycled content. One point is awarded if the sum of the post-consumer recycled content plus one-half of the post-industrial recycled content constitutes at least 7.5% of the total value of the materials in the project. The value of the recycled content of a material is the weight of the recycled content in the item divided by the weight of all materials in that item, and then multiplied by the total cost of the item.

Supplementary cementitious materials (SCMs), such as fly ash, silica fume, and slag cement, are considered post-industrial materials. LEED Canada – NC makes special provisions for SCMs due to their light weight and environmental impact. Instead of using the weight of the concrete to determine recycled content, the weight of the SCMs is divided by the weight of the total cementitious material, then multiplied by two, and that number is multiplied by the cost of the concrete and formwork. The intent is that a concrete building with 25% of the portland cement replaced with fly ash should be able to achieve 1 point and a concrete building with 40% replacement of portland cement with fly ash should be able to achieve 2 points. Using fly ash replacement levels for portland cement greater than 25% are not routine. Actual limits are based on experience and concrete performance in the field or laboratory. Contact your local ready-mix concrete supplier to determine what fly ash is available and to verify its performance in quality concrete.

Using recycled concrete or slag as aggregate instead of extracted aggregates would also qualify as post-consumer.

Although most reinforcing bar is manufactured from recycled steel, and would probably qualify, it would not be considered as part of concrete. This credit is worth 1 point for the quantities quoted above and 2 points if the quantities are doubled to 15% combined post-consumer plus one-half post-industrial recycled content.

(Materials Credit 5)

This credit supports the use of indigenous materials and reduced transportation distances. It also recognizes the reduced impacts of rail or ship compared to truck. The requirements of this credit state: “Specify a minimum of 10% of building materials that are extracted, processed, and manufactured within a radius of 800 km (500 miles) OR specify a minimum of 10% of building materials that are extracted, processed, manufactured, and shipped primarily by rail or water within a radius of 2400 km (1500 miles).” Combinations of the first criterion (for trucks) and the second (for rail or water) can also be used.

Ready-mix plants generally use aggregates that are extracted within 160 km (100 miles) of the plant. Cement and supplementary cementitious materials used for buildings are often manufactured within 800 km (500 miles) of a job site. Concrete made with regional cementitious materials and aggregates will often qualify since ready-mix plants are generally within 160 km (100 miles) of a job site. Reinforcing steel is also often manufactured within 800 km (500 miles) of a job site, and is typically made from recycled materials from the same region. The percentage of materials is calculated on a cost basis. This credit is worth 1 point.

An additional point is earned if the above quantities are doubled to 20%.

(Materials Credit 8)

LEED Canada – NC provides an incentive for durable buildings and recognizes resources required to replace materials with a short service life. This credit requires that a Building Durability Plan be developed and implemented in accordance with portions of CSA S478-95 (R2001) – Guidelines on Durability in Buildings for the construction and preoccupancy phases of the building. The guidelines require (1) an appropriate design service life for components and assemblies, (2) appropriate materials and designs so the design service life is exceeded, (3) documentation, and (4) quality assurance. This credit is worth 1 point.

In addition to the points discussed above, 4 points are available under Innovation & Design Process. These points can be applied for if an innovative green design strategy is used that does not fit into the point structure of the five LEED categories or if it goes significantly beyond a credit requirement and demonstrates exceptional environmental performance. One point is also provided if a principal participant of the project team is a LEED Accredited Professional. The concrete industry has LEED-experienced professionals available to help maximize the points for concrete.

Points must be documented according to LEED procedures in order to be earned.

Using concrete can increase the points awarded to a building under the LEED system. The potential available points that can be earned through the use of concrete range from 13 to 23.

LEED certification is solely a voluntary program; however, obtaining a LEED certification projects a positive environmental image to the community. Additionally, meeting many of the green building practices can result in energy and cost savings over the life of the structure. Other advantages include better indoor air quality and plenty of daylight. Studies have shown that workers in these environments have increased labor productivity, job retention, and days worked. These benefits contribute directly to a company’s profits because salaries—which are about ten times higher than rent, utilities, and maintenance combined—are the largest expense for most companies occupying office space. Students in these environments have higher test scores and lower absenteeism.

Many cities and government agencies require LEED green building certification for new public buildings. These include Greater Vancouver Regional District, City of Vancouver, Alberta Infrastructure, City of Calgary Sustainable Buildings Policy, Manitoba Hydro, Public Works and Government Services Canada, BC Buildings Corporation and La Societe Immobilliere du Quebec. Support for green buildings has increased rapidly each year over the last five years.

LEED Canada – NC promotes environmentally conscious buildings for the improvement of outdoor and indoor building quality and the reduction of waste during the building process. Concrete can be used in conjunction with the LEED program to earn a LEED certification.

Concrete Durability

Longer Lasting, More Efficient Structures

Durability is a significant sustainable attribute of concrete because it will not rust, rot, or burn, requiring less energy and resources over time to repair or replace. Concrete builds durable, long-lasting structures including sidewalks, building foundations and envelopes, as well as roadways and bridges. As the most widely used building material in the world, concrete structures have withstood the test of time for more than 2,000 years. Because of its longevity, it can be a viable solution for environmentally responsible design.

Click below to visit the Portland Cement Association’s website for more information on concrete durability.

Concrete Pavements

The Sustainable Benefits

Life cycle assessment research by the Athena Institute shows the energy use footprint for concrete pavement structures is substantially lower than asphalt pavement structures.

- Athena Institute study, A Life Cycle Perspective on Concrete and Asphalt Roadways: Embodied Primary Energy and Global Warming Potential identified the embodied primary energy used ranged from 2.3 to 5.2 times more for asphalt pavement structures.

- The embodied primary energy of a product is equal to the primary energy plus the feedstock energy.

- Primary energy refers to the quantity of fossil fuel required to manufacture, supply, and maintain a product over a specified period of time, usually 50 years.

- Feedstock energy is the gross combustion heat value of the fossil hydrocarbon material input into the product which is a source of energy, such as liquid bitumen, but is not being used as an energy source.

- ISO 14040 section 4.2.3.3.2 states, “Energy inputs and outputs shall be treated as any other input or output to an LCA. The various types of energy inputs and outputs shall include inputs and outputs relevant for the production and delivery of fuels, feedstock energy and process energy used within the system being modeled.” Therefore, gross combustion heat value of liquid bitumen must be included in any LCA analysis.

National Research Council of Canada (NRC) studies comparing the fuel consumption of heavy vehicles operating on different types of pavement surfaces concluded that there is a savings ranging from of 0.8 to 6.9 percent when operating on concrete pavement compared to asphalt pavement.

- The hypothesis for the savings is based on heavy vehicles causing greater deflection on flexible pavements than on rigid pavements. This increased deflection of the pavement absorbs part of the vehicles rolling energy that would otherwise be available to propel the vehicle.

- Several variables were included in the analysis such as pavement type, pavement roughness, vehicle type, different loading conditions, different speeds, different seasons (spring, summer day, summer night, fall and winter), pavement grade and wind speed.

- Fuel savings are based on comparing smooth asphalt pavements versus smooth concrete pavements.

- Phase II study demonstrated statistically significant fuel savings for tractor tanker semi-trailers (5-axle) vehicles traveling on smooth roads from 4.1% to 6.9% depending on operating speed.

- Phase III study demonstrated statistically significant fuel savings for tractor van semi-trailers (6-axle) vehicles traveling on smooth roads from 0.8% to 3.9% depending on operating speed. The summer night data was excluded from the analysis, even though it was in concrete’s favor, due to it not being statistically significant.

A Case study, by the Transtec group, on FHWA Long-Term Pavement Performance data demonstrated that the rate of change of pavement roughness is significantly greater for the asphalt pavement sites than similar concrete pavement sites.

- Although the asphalt sites had superior initial smoothness, roughness of the asphalt sites increased 69.9 % over the 8 to 9 year evaluation period compared with 3.7 % for the concrete pavements.

- Concrete pavement sections carried 3.5 times more traffic than the asphalt sections.

- The rate of change of pavement roughness is significantly greater for the asphalt sites than the concrete sites – 53 times more for the Kansas sites – normalized to accumulated traffic.

This program is designed to provide owners and customers with the highest degree of assurance that the concrete facility, company and products they have selected to supply their project, address sound and responsible Environmental and Sustainable Development Facilities management and operations, and that manufacturing practices and protocols support their choice of Responsible Material Procurement. It identifies Environmental and Sustainable Development stewardship and responsibility of the facility’s processes following LEED rating system and categories to minimize the environmental footprint.

This source can be old in-situ concrete or returned fresh concrete that is allowed to harden. This concrete can be 100% recycled into a number of practical uses, decreasing the requirement to use virgin non-renewable resources. This recycled material can be used for road base, backfill, stabilization or concrete aggregate; therefore, keeping it out of landfills.

Please note that it is becoming standard practice for fresh returned concrete to be immediately reclaimed or reused in its plastic state, diverting this from any land fill or other process.

SCMs are widely used and accepted as good practice in today’s cement and concrete production. Two of the more common SCMs are slag and fly ash which are by-products of steel manufacturing and thermal power generation respectively. Cement and concrete incorporating SCMs will have a reduced CO2 footprint, yet saving the environment by preventing these hazardous materials ending up in the landfill sites.

Paved surfaces (such as highways, roads, runways, parking areas, sidewalks, and driveways) typically constitute about 30 to 40% of developed urban areas. In the past few decades, the bane of urban cities has been the increased heating of the city by sunlight due to dark, heat-absorbing materials used in the construction of pavements and buildings. Urban areas are oftentimes up to 2 to 4°C warmer than the surrounding rural area, creating “urban heat islands.” Concrete pavement provides reflective surfaces that minimize the urban heat island effect because it is lighter in color with higher solar reflectance (albedo), also saving energy by reducing the demand for air conditioning and reducing power plant emissions. Cooler air can also reduce air pollution by slowing the chemical reactions that produce smog.

Albedo, or solar reflectance, is the ratio of reflected solar radiation to the total amount that falls on that surface, known as incident solar radiation. Albedo values range from 0, for perfect absorbers, to 1, for perfect reflectors. In pavement structures, the topmost surface is the only layer which affects albedo. Therefore, pavement type selection should also include a consideration of albedo where heat generation is a concern. Field measurements indicate that new, cured gray-cement concrete pavement has an albedo in the range of 0.35 – 0.40. As concrete ages, it tends to darken because of dirt and tire wear, so older concretes have albedos in the range of 0.20 – 0.30. The use of white cements and slag cements can also influence a concrete’s albedo immensely. New asphalt is very dark, so it has an albedo of 0.05 – 0.10, and aged asphalt has an albedo of 0.10 – 0.15. Research for Transport Canada (1977) found an approximately 40% drop in luminance levels under the same illumination conditions for concrete roads overlaid with bituminous asphalt. Thus concrete surface provide safer roadways for public driving, in particular, in pedestrian areas such as central business district streets and plazas, parking lots, parking garages, and around shopping malls, lighting enhances safety, and can help improve commerce and maintain property values.

This a paving technique for a pavement consisted of two layers, wet on wet, with the top layer consisting of a special mix to provide a quiet, durable and friction resistance surface. The bottom layer is normally a mixture of virgin aggregate with recycled concrete/asphalt aggregates and higher volumes of SCMs incorporated in it, which would normally not meet the top surface high quality requirements. This helps to minimize the use of virgin aggregate resources, yet prevent old concrete/asphalt being dumped in the landfill sites.

This process rebuilds worn out asphalt pavements by recycling the existing roadway. The old asphalt and base materials are pulverized, mixed with cement and water, and compacted to produce a strong, durable, stabilized base for either an asphalt or concrete surface. FDR uses the old deteriorated asphalt and base material for the new roadway base. There’s no need to haul in aggregate or haul out old asphalt material for disposal, greatly reducing the construction truck traffic. FDR with cement conserves virgin construction materials and makes smart economic and strategic sense. Continuing to exhaust these valuable resources to rebuild existing roads only propagates and accelerates the problem. Additionally, if old asphalt and base materials are not recycled, they must be disposed of or stockpiled, increasing transportation costs and occupying valuable landfill space.

As identified in the 2008 Canadian Cement Industry Sustainability Report the Canadian cement industry is committed to the continued reduction of its environmental footprint. For example, between 1990 and 2006, Canada’s cement manufactures improved energy efficiency of their production operations by 11 % per tonne of cement, and reduced the greenhouse gas emissions (GHG) intensity of their production by 6.4 % per tonne of cement. Several additional methods to reduce the industries energy and CO2 footprints are currently being pursued including the following:

-

Reducing the clinker to cement ratio by intergrinding the cement with up to 15 % limestone. A new CSA Portland Limestone Cement standard will soon be released and a revision to the CSA concrete standard is to accompany it.

-

Increasing the use of supplementary cementing materials (SCMs) which again decreases the amount of cement being used, thereby, also decreasing the CO2 and energy footprint.

-

Using alternative and renewable energies in the cement kilns as a replacement for coke or coal can also help reduce GHG emissions and energy use. The more these fuels are accepted and utilized, as in Europe, the greater the GHG emissions reductions will be.

A Low Carbon Concrete Future

5 Low Carbon Levers

It is the material that forms the backbone of our modern world and has so dramatically improved the quality of our lives, it is hard to realize how much this material is integrated with how we work, live, laugh, and play every day. It offers durability, strength, resilience, safety and so much more in buildings and infrastructure all around you. The concrete industry in British Columbia, Canada, and around the world, is taking action to actively and openly address our industry’s global-warming challenges with goals of net-zero carbon by 2050 with important milestones in 2030.

So as we all accelerate together on this journey, we’re pleased to share that there are

Lower Carbon Concrete Levers Already Available Today…